Choosing the Right Wholesale Wood Cutting Machine for Your Workshop

June 1, 2025 | by woodchanna@gmail.com

Introduction

Woodworking is a timeless craft that requires precision, skill, and the right tools to create beautiful and functional pieces of furniture, cabinetry, and other wooden items. One essential tool that every woodworking workshop needs is a wood cutting machine. With the advancement of technology, there are now a variety of wood cutting machines available on the market, each with its own unique features and capabilities. In this article, we will discuss how to choose the right wholesale wood cutting machine for your workshop, focusing on technical specifications, use cases in woodworking factories, advantages over other machines, and why this machine is ideal for importers and traders in various countries such as Egypt, Pakistan, Vietnam, Kenya, Saudi Arabia, UAE, Russia, and global markets.

When it comes to choosing a wholesale wood cutting machine for your workshop, there are several important factors to consider. The first thing to look at is the technical specifications of the machine. This includes the cutting capacity, maximum cutting depth, motor power, blade speed, and cutting angles. These specifications will determine the machine’s ability to handle different types of wood and the precision of the cuts it can make.

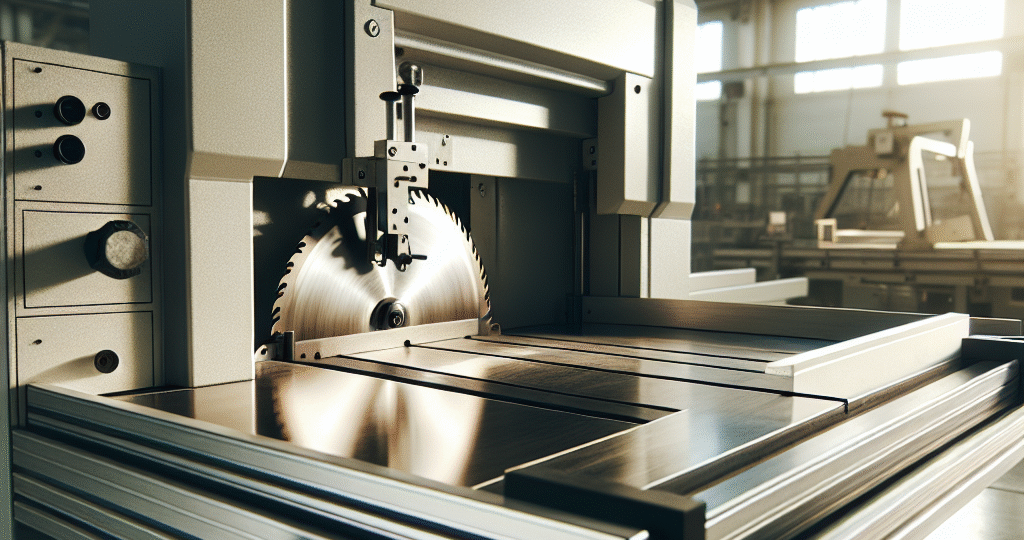

Another important factor to consider is the type of wood cutting machine that best suits your needs. Some common types of wood cutting machines include table saws, band saws, panel saws, and CNC routers. Each type of machine has its own advantages and disadvantages, so it’s important to choose the one that best fits your specific woodworking needs. For example, table saws are great for making straight cuts, while band saws are ideal for cutting curves and irregular shapes. Panel saws are used for cutting large sheets of wood, and CNC routers are perfect for intricate and precise cuts.

In woodworking factories, wood cutting machines play a crucial role in increasing productivity and efficiency. These machines are used to cut, shape, and trim wood pieces quickly and accurately, saving time and labor costs. Wood cutting machines can also help reduce waste by optimizing the use of raw materials and minimizing errors in the cutting process. In addition, these machines can handle a wide range of wood types and sizes, making them versatile tools for woodworking factories of all sizes.

One of the main advantages of wholesale wood cutting machines is that they are cost-effective for importers and traders looking to purchase large quantities of machines for their businesses. Buying wholesale allows buyers to get discounted prices and bulk discounts, saving money in the long run. Additionally, wholesale wood cutting machines are often of higher quality and come with warranties and after-sales support, ensuring that buyers get a reliable and durable product.

Wholesale wood cutting machines are also ideal for importers and traders in countries such as Egypt, Pakistan, Vietnam, Kenya, Saudi Arabia, UAE, Russia, and global markets. These countries have a growing demand for woodworking machinery due to the increasing popularity of woodworking as a hobby and as a professional trade. By importing wholesale wood cutting machines, traders and importers can meet this demand and supply high-quality machines to woodworking workshops and factories in these countries.

One platform that connects buyers with reliable suppliers of wholesale wood cutting machines is woodenb2b.com. Woodenb2b.com is an online marketplace that specializes in connecting buyers and sellers of woodworking machinery, tools, and materials. Buyers can browse a wide selection of wood cutting machines from trusted suppliers, compare prices and specifications, and place orders directly through the website. Woodenb2b.com also offers secure payment options, fast shipping, and excellent customer service to ensure a smooth and hassle-free buying experience for buyers.

In conclusion, choosing the right wholesale wood cutting machine for your workshop is essential for increasing productivity, efficiency, and quality in woodworking. By considering technical specifications, use cases in woodworking factories, advantages over other machines, and the benefits for importers and traders in various countries, woodworking businesses can find the perfect machine to meet their needs. With platforms like woodenb2b.com, buyers can easily connect with reliable suppliers and purchase high-quality wood cutting machines for their workshops and factories.

Why Importers and Factories Should Choose a Sliding Table Saw Machine

Sliding table saws are essential tools in modern woodworking industries due to their precision, speed, and versatility. Whether you’re importing into Egypt, Kenya, or Vietnam, this machine can significantly improve productivity.

Technical Specifications

- Power: 4 kW – 7.5 kW

- Blade Diameter: 300mm – 400mm

- Adjustable Cutting Depth and Angle

- Industrial-grade Aluminum Table

Where to Buy Quality Sliding Table Saws?

If you’re looking to source directly from China or need trusted suppliers in the Middle East, Africa, or Asia, woodenb2b.com connects importers and factories with verified machinery suppliers.

📌 Looking for more information? Visit us at woodenb2b.com — Your B2B Source for Woodworking Machinery.

RELATED POSTS

View all