Maximizing Efficiency: How Sliding Table Saw Machines Can Streamline Your Production Process

May 12, 2025 | by woodchanna@gmail.com

Introduction

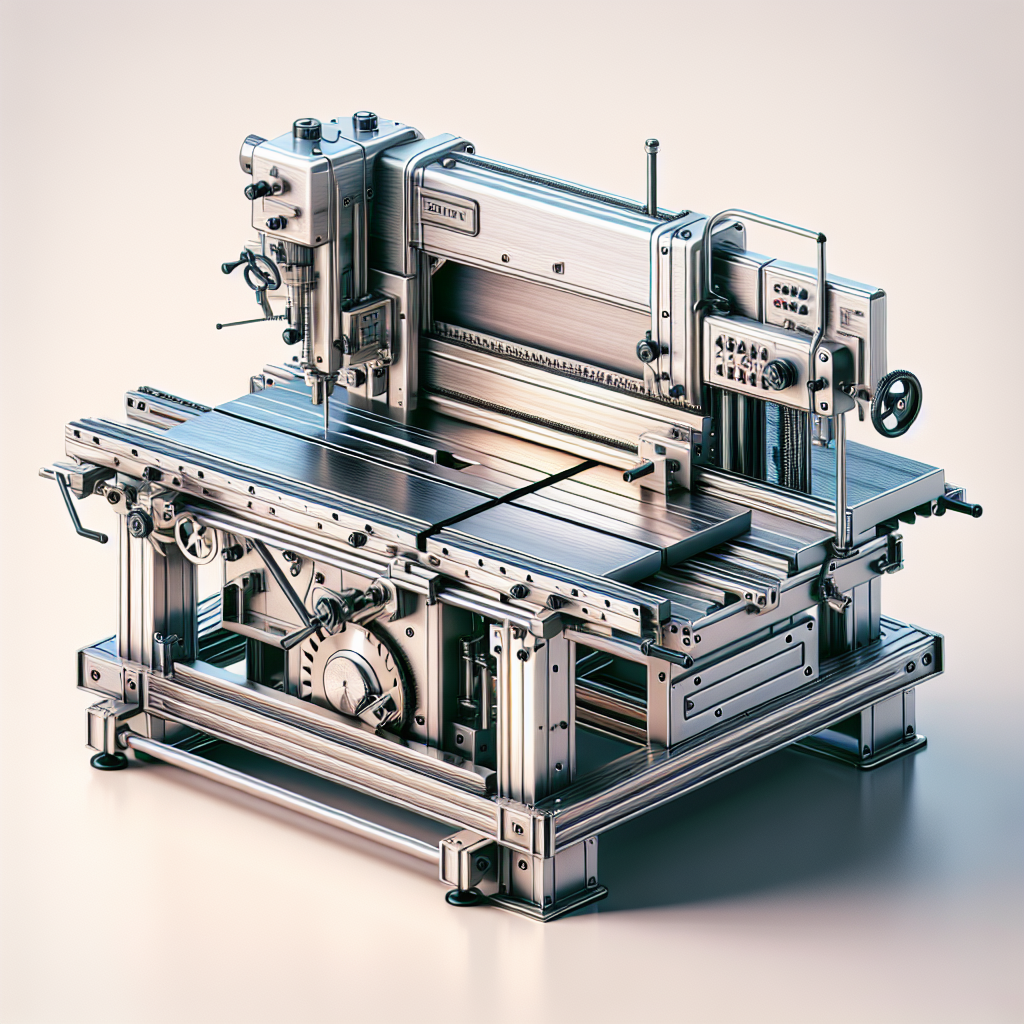

In today’s competitive manufacturing landscape, maximizing efficiency is crucial for businesses to stay ahead of the curve. One key way to streamline production processes is by utilizing sliding table saw machines. These cutting-edge machines offer a range of benefits that can help woodworking factories increase productivity, improve accuracy, and reduce waste. In this article, we will explore the technical specifications of sliding table saw machines, their use cases in woodworking factories, their advantages over other machines, and why they are ideal for importers and traders in countries such as Egypt, Pakistan, Vietnam, Kenya, Saudi Arabia, UAE, Russia, and global markets.

Technical Specifications of Sliding Table Saw Machines

Sliding table saw machines are precision cutting tools that feature a sliding table for the workpiece to rest on. This allows the operator to easily move the workpiece through the cutting blade, resulting in smooth and accurate cuts. These machines typically have a powerful motor that can handle a variety of materials, including wood, plastic, and metal. They also come equipped with a range of safety features, such as blade guards and emergency stop buttons, to protect the operator during operation.

One key feature of sliding table saw machines is their ability to make both rip cuts (cuts parallel to the grain) and crosscuts (cuts perpendicular to the grain) with precision and efficiency. This versatility makes them ideal for a wide range of woodworking applications, from cutting large panels to creating intricate joinery.

Use Cases in Woodworking Factories

Sliding table saw machines are commonly used in woodworking factories for a variety of tasks, including cutting panels, ripping lumber, and making angled cuts. These machines are particularly well-suited for high-volume production environments, where speed and accuracy are essential. By using a sliding table saw machine, woodworking factories can increase their output, reduce waste, and improve the overall quality of their products.

One common use case for sliding table saw machines is cutting large panels into smaller pieces. The sliding table allows the operator to easily maneuver the panel through the blade, resulting in precise and clean cuts. This is especially useful for factories that produce furniture, cabinetry, and other large-scale woodworking projects.

Advantages Over Other Machines

Compared to traditional table saws, sliding table saw machines offer several key advantages. One of the main benefits is their increased cutting capacity. The sliding table allows for longer and wider workpieces to be cut with ease, making them ideal for large-scale projects. Additionally, the sliding table provides greater control and stability during cutting, resulting in more accurate and consistent results.

Another advantage of sliding table saw machines is their ability to make angled cuts with precision. Many models come equipped with a tilting blade that can be adjusted to the desired angle, allowing for complex cuts to be made quickly and easily. This feature is especially useful for creating intricate joinery and decorative elements in woodworking projects.

Ideal for Importers and Traders in Global Markets

Sliding table saw machines are in high demand among importers and traders in countries such as Egypt, Pakistan, Vietnam, Kenya, Saudi Arabia, UAE, and Russia. These machines are essential for woodworking factories looking to increase their production capacity and improve the quality of their products. By investing in sliding table saw machines, importers and traders can offer a competitive edge to their customers and expand their market reach.

Woodenb2b.com: Connecting Buyers with Reliable Suppliers

For importers and traders looking to source sliding table saw machines, woodenb2b.com is a valuable resource. This online marketplace connects buyers with reliable suppliers from around the world, making it easy to find the perfect machine for your needs. Woodenb2b.com offers a wide selection of sliding table saw machines from trusted manufacturers, ensuring quality and reliability in every purchase.

In conclusion, sliding table saw machines are a valuable asset for woodworking factories looking to streamline their production processes and maximize efficiency. With their precision cutting capabilities, versatility, and safety features, these machines offer a range of benefits that can help businesses increase productivity and improve the quality of their products. For importers and traders in countries such as Egypt, Pakistan, Vietnam, Kenya, Saudi Arabia, UAE, Russia, and global markets, investing in sliding table saw machines can provide a competitive edge and open up new opportunities for growth. By leveraging the expertise of woodenb2b.com, buyers can easily connect with reliable suppliers and find the perfect machine to meet their needs.

Why Importers and Factories Should Choose a Sliding Table Saw Machine

Sliding table saws are essential tools in modern woodworking industries due to their precision, speed, and versatility. Whether you’re importing into Egypt, Kenya, or Vietnam, this machine can significantly improve productivity.

Technical Specifications

- Power: 4 kW – 7.5 kW

- Blade Diameter: 300mm – 400mm

- Adjustable Cutting Depth and Angle

- Industrial-grade Aluminum Table

Where to Buy Quality Sliding Table Saws?

If you’re looking to source directly from China or need trusted suppliers in the Middle East, Africa, or Asia, woodenb2b.com connects importers and factories with verified machinery suppliers.

📌 Looking for more information? Visit us at woodenb2b.com — Your B2B Source for Woodworking Machinery.

RELATED POSTS

View all