All blog posts

Explore the world of design and learn how to create visually stunning artwork.

The Benefits of Investing in Wholesale Wood Cutting Machines for Your Manufacturing Business

June 1, 2025 | by woodchanna@gmail.com

فوائد الاستثمار في آلات قطع الخشب بالجملة لعملك

June 1, 2025 | by woodchanna@gmail.com

Choosing the Right Wholesale Wood Cutting Machine for Your Workshop

June 1, 2025 | by woodchanna@gmail.com

تعظيم الكفاءة: نصائح لاستخدام آلات قطع الخشب بالجملة

June 1, 2025 | by woodchanna@gmail.com

Maximizing Efficiency: How Wholesale Wood Cutting Machines Can Boost Your Business

June 1, 2025 | by woodchanna@gmail.com

كيفية اختيار أفضل آلة قطع الخشب بالجملة لاحتياجاتك

May 31, 2025 | by woodchanna@gmail.com

Top 10 Wholesale Wood Cutting Machines for Efficient Production

May 31, 2025 | by woodchanna@gmail.com

Introduction

Wood cutting machines are essential tools for woodworking factories, allowing for precise and efficient cutting of wood materials. Investing in wholesale wood cutting machines for your manufacturing business can provide a wide range of benefits, from increased productivity to cost savings. In this article, we will explore the technical specifications, use cases in woodworking factories, advantages over other machines, and why these machines are ideal for importers and traders in various global markets.

Technical Specifications

Wood cutting machines come in different types and sizes, each designed for specific cutting tasks. Some of the common types of wood cutting machines include CNC routers, panel saws, band saws, and table saws. These machines can vary in terms of cutting capacity, speed, accuracy, and power consumption.

When choosing a wood cutting machine for your manufacturing business, it is important to consider the technical specifications that best suit your production needs. For example, if you need to cut large panels of wood, a panel saw with a high cutting capacity would be ideal. On the other hand, if you require intricate and precise cuts, a CNC router with advanced cutting capabilities would be more suitable.

Use Cases in Woodworking Factories

Wood cutting machines are used in various woodworking factories for cutting, shaping, and finishing wood materials. These machines are versatile tools that can handle a wide range of cutting tasks, from simple straight cuts to complex shapes and designs. Some of the common use cases of wood cutting machines in woodworking factories include:

– Cutting wooden panels for furniture manufacturing

– Shaping wooden components for cabinetry and millwork

– Creating intricate designs and patterns on wood surfaces

– Cutting lumber for construction and woodworking projects

Advantages Over Other Machines

Wood cutting machines offer several advantages over traditional manual cutting methods and other cutting machines. Some of the key advantages of investing in wood cutting machines for your manufacturing business include:

– Increased productivity: Wood cutting machines can significantly increase production output by automating the cutting process and reducing manual labor.

– Precision and accuracy: Wood cutting machines offer precise and accurate cuts, ensuring high-quality finished products.

– Cost savings: By reducing material wastage and improving cutting efficiency, wood cutting machines can help lower production costs.

– Versatility: Wood cutting machines can handle a wide range of cutting tasks, making them versatile tools for woodworking factories.

– Safety: Wood cutting machines are equipped with safety features to protect operators from accidents and injuries.

Ideal for Importers and Traders in Global Markets

Wood cutting machines are in high demand in global markets, especially in countries with a thriving woodworking industry such as Egypt, Pakistan, Vietnam, Kenya, Saudi Arabia, UAE, Russia, and others. Importers and traders in these markets can benefit from investing in wholesale wood cutting machines to meet the growing demand for wood products.

Importers and traders can source wood cutting machines from reliable suppliers through online platforms such as woodenb2b.com. Woodenb2b.com is a leading online marketplace that connects buyers with reputable suppliers of woodworking machinery and equipment. By using woodenb2b.com, importers and traders can easily find and purchase high-quality wood cutting machines at competitive prices, ensuring a smooth and efficient procurement process.

In conclusion, investing in wholesale wood cutting machines for your manufacturing business can provide numerous benefits, from increased productivity to cost savings. These machines offer advanced technical specifications, versatile use cases in woodworking factories, and advantages over other cutting machines. Importers and traders in global markets can leverage the benefits of wood cutting machines to meet the growing demand for wood products. By sourcing wood cutting machines from reliable suppliers through platforms like woodenb2b.com, businesses can ensure a steady supply of high-quality machinery for their production needs.

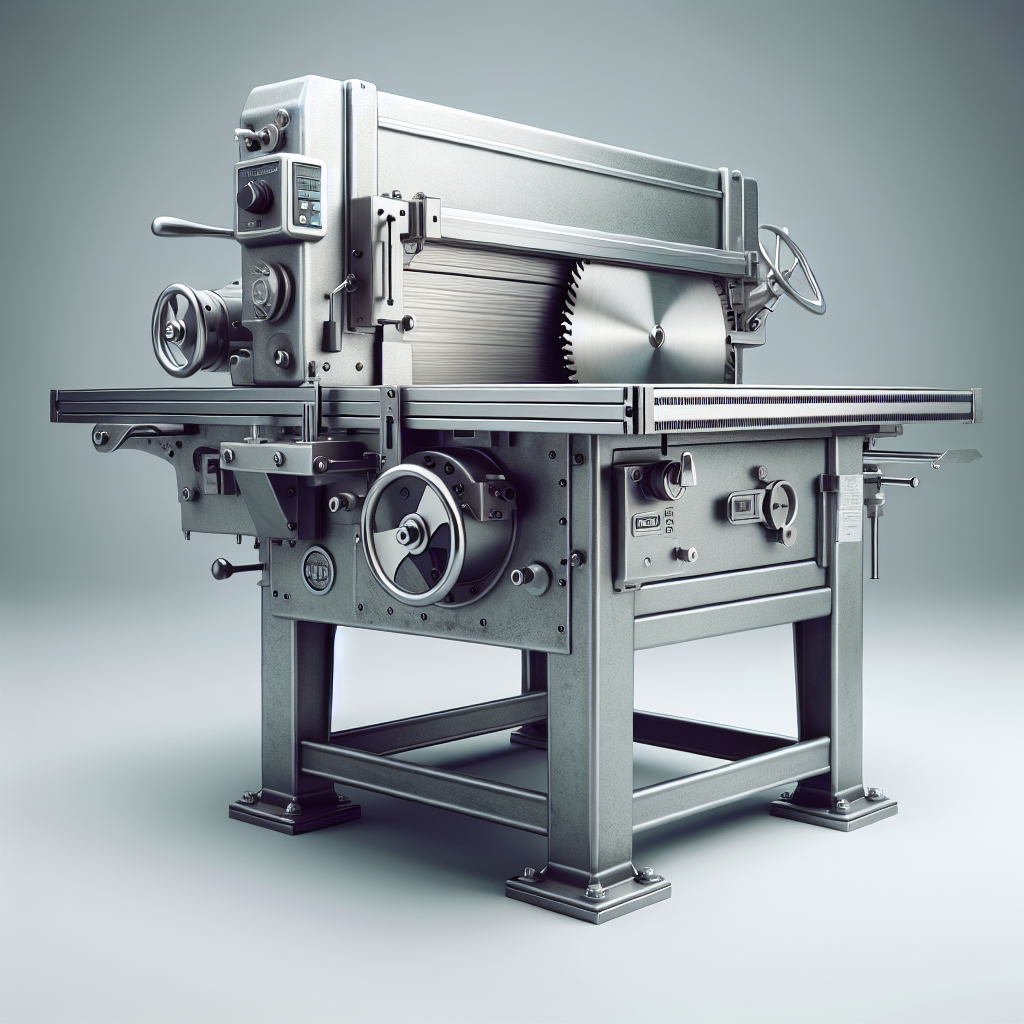

Why Importers and Factories Should Choose a Sliding Table Saw Machine

Sliding table saws are essential tools in modern woodworking industries due to their precision, speed, and versatility. Whether you’re importing into Egypt, Kenya, or Vietnam, this machine can significantly improve productivity.

Technical Specifications

- Power: 4 kW – 7.5 kW

- Blade Diameter: 300mm – 400mm

- Adjustable Cutting Depth and Angle

- Industrial-grade Aluminum Table

Where to Buy Quality Sliding Table Saws?

If you’re looking to source directly from China or need trusted suppliers in the Middle East, Africa, or Asia, woodenb2b.com connects importers and factories with verified machinery suppliers.

📌 Looking for more information? Visit us at woodenb2b.com — Your B2B Source for Woodworking Machinery.