Top 10 Wholesale Wood Cutting Machines for Efficient Production

May 31, 2025 | by woodchanna@gmail.com

Introduction

Wood cutting machines have revolutionized the woodworking industry by increasing efficiency, precision, and productivity. For woodworking factories and manufacturers, investing in high-quality wholesale wood cutting machines is essential for ensuring smooth operations and meeting production demands. In this article, we will explore the top 10 wholesale wood cutting machines that are ideal for efficient production in woodworking factories. These machines are not only suitable for importers and traders in countries like Egypt, Pakistan, Vietnam, Kenya, Saudi Arabia, UAE, Russia, and global markets, but also offer a range of technical specifications and advantages over other machines.

1. CNC Wood Router:

CNC wood routers are versatile machines that use computer numerical control technology to cut, carve, and shape wood with precision. These machines are ideal for producing intricate designs, engravings, and patterns on wooden surfaces. With high-speed cutting capabilities and automatic tool changing features, CNC wood routers are perfect for woodworking factories looking to streamline their production processes.

2. Panel Saw:

Panel saws are used for cutting large sheets of wood into smaller, more manageable pieces. These machines are equipped with powerful saw blades that can make straight and precise cuts quickly and efficiently. Panel saws are essential for woodworking factories that work with large volumes of sheet materials such as plywood, MDF, and particleboard.

3. Band Saw:

Band saws are versatile machines that use a continuous loop of teethed metal to cut through wood. These machines are ideal for creating curved or irregular shapes in wood, making them essential for furniture manufacturers and carpentry workshops. Band saws are known for their accuracy and smooth cutting capabilities, making them a popular choice for woodworking factories.

4. Wood Planer:

Wood planers are used for smoothing and flattening rough-sawn lumber, making them essential for preparing wood for further processing. These machines use rotating blades to remove imperfections and create a smooth, uniform surface on wooden boards. Wood planers are ideal for woodworking factories that require precise and consistent thickness in their wood products.

5. Wood Lathe:

Wood lathes are used for turning cylindrical wooden pieces to create intricate designs and shapes. These machines are essential for producing wooden furniture components, decorative items, and architectural details. Wood lathes are known for their precision and versatility, making them a valuable asset for woodworking factories looking to add decorative elements to their products.

6. Wood Shaper:

Wood shapers are specialized machines that use rotating cutters to shape and profile wood. These machines are ideal for creating decorative moldings, edges, and profiles on wooden surfaces. Wood shapers are essential for woodworking factories that produce custom furniture, cabinetry, and architectural millwork.

7. Edge Banding Machine:

Edge banding machines are used for applying decorative edges to wooden panels and boards. These machines use hot melt adhesive to bond edge banding material to the edges of wood, creating a seamless and durable finish. Edge banding machines are essential for woodworking factories that produce furniture, cabinets, and other wood products with finished edges.

8. Dust Collector:

Dust collectors are essential machines for maintaining a clean and safe working environment in woodworking factories. These machines use powerful suction to capture and filter dust and debris generated during wood cutting and processing. Dust collectors help reduce airborne particles, improve air quality, and prevent respiratory issues among workers in woodworking factories.

9. Wood Moisture Meter:

Wood moisture meters are used for measuring the moisture content of wood to ensure proper drying and storage conditions. These handheld devices are essential for woodworking factories that work with green or kiln-dried lumber. Wood moisture meters help prevent warping, cracking, and other defects caused by improper moisture levels in wood products.

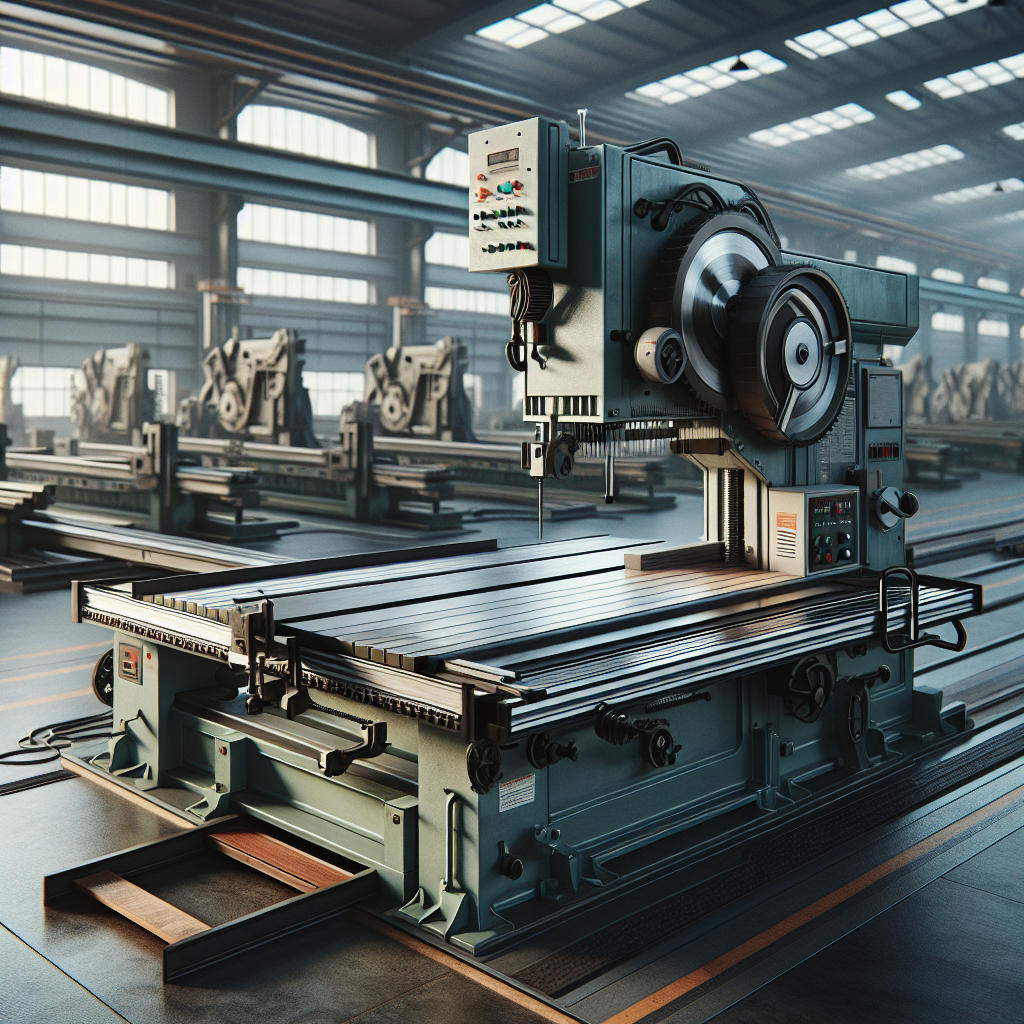

10. Wood CNC Machining Center:

Wood CNC machining centers combine the capabilities of CNC routers, mills, and lathes into a single machine. These versatile machines are ideal for producing complex wooden components with precision and efficiency. Wood CNC machining centers are essential for woodworking factories that require high-speed machining, multi-axis cutting, and automated tool changing capabilities.

Advantages of Wholesale Wood Cutting Machines:

– Increased efficiency and productivity in woodworking factories.

– Precision cutting and shaping of wood for high-quality products.

– Versatility in producing a wide range of wooden components and products.

– Reduced labor costs and manual labor for repetitive tasks.

– Improved safety and working conditions for factory workers.

– Consistent and uniform results in wood cutting and processing.

Woodenb2b.com: Connecting Buyers with Reliable Suppliers

Woodenb2b.com is a leading online platform that connects buyers with reliable suppliers of wood cutting machines and woodworking equipment. This platform offers a wide range of wholesale wood cutting machines from trusted manufacturers and suppliers worldwide. By using woodenb2b.com, importers and traders in Egypt, Pakistan, Vietnam, Kenya, Saudi Arabia, UAE, Russia, and global markets can easily find and source high-quality wood cutting machines for their woodworking factories.

Woodenb2b.com provides a user-friendly interface for buyers to browse, compare, and select wood cutting machines based on their technical specifications, price range, and supplier information. This platform also offers secure payment options, buyer protection, and timely delivery of wood cutting machines to ensure a seamless and hassle-free purchasing experience.

In conclusion, investing in top-quality wholesale wood cutting machines is essential for woodworking factories looking to improve efficiency, productivity, and product quality. These machines offer a range of technical specifications and advantages over other machines, making them ideal for importers and traders in Egypt, Pakistan, Vietnam, Kenya, Saudi Arabia, UAE, Russia, and global markets. By using platforms like woodenb2b.com, buyers can easily connect with reliable suppliers and source high-quality wood cutting machines for their woodworking operations.

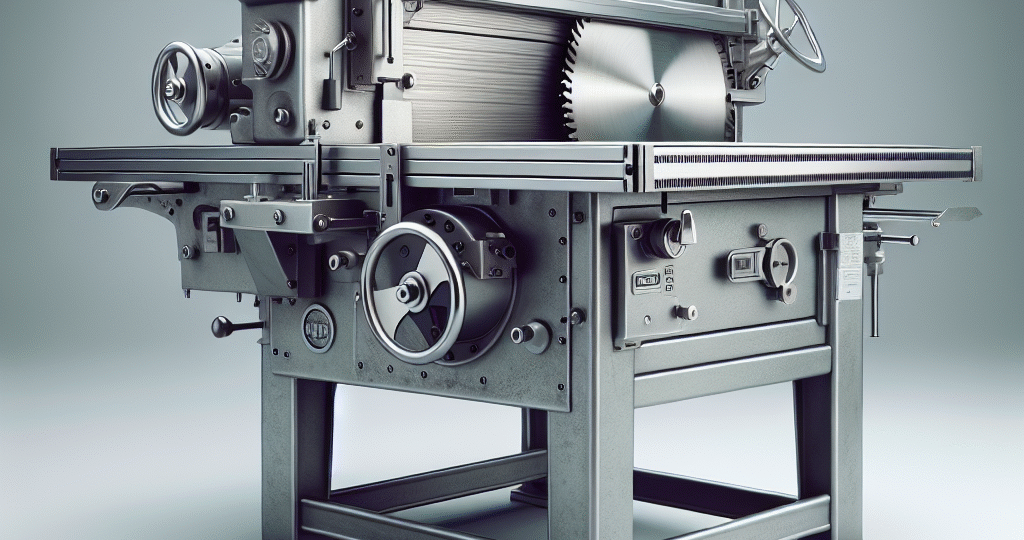

Why Importers and Factories Should Choose a Sliding Table Saw Machine

Sliding table saws are essential tools in modern woodworking industries due to their precision, speed, and versatility. Whether you’re importing into Egypt, Kenya, or Vietnam, this machine can significantly improve productivity.

Technical Specifications

- Power: 4 kW – 7.5 kW

- Blade Diameter: 300mm – 400mm

- Adjustable Cutting Depth and Angle

- Industrial-grade Aluminum Table

Where to Buy Quality Sliding Table Saws?

If you’re looking to source directly from China or need trusted suppliers in the Middle East, Africa, or Asia, woodenb2b.com connects importers and factories with verified machinery suppliers.

📌 Looking for more information? Visit us at woodenb2b.com — Your B2B Source for Woodworking Machinery.

RELATED POSTS

View all