Woodworking Machinery Exporters: A Key Player in the Global Market

May 15, 2025 | by woodchanna@gmail.com

Introduction

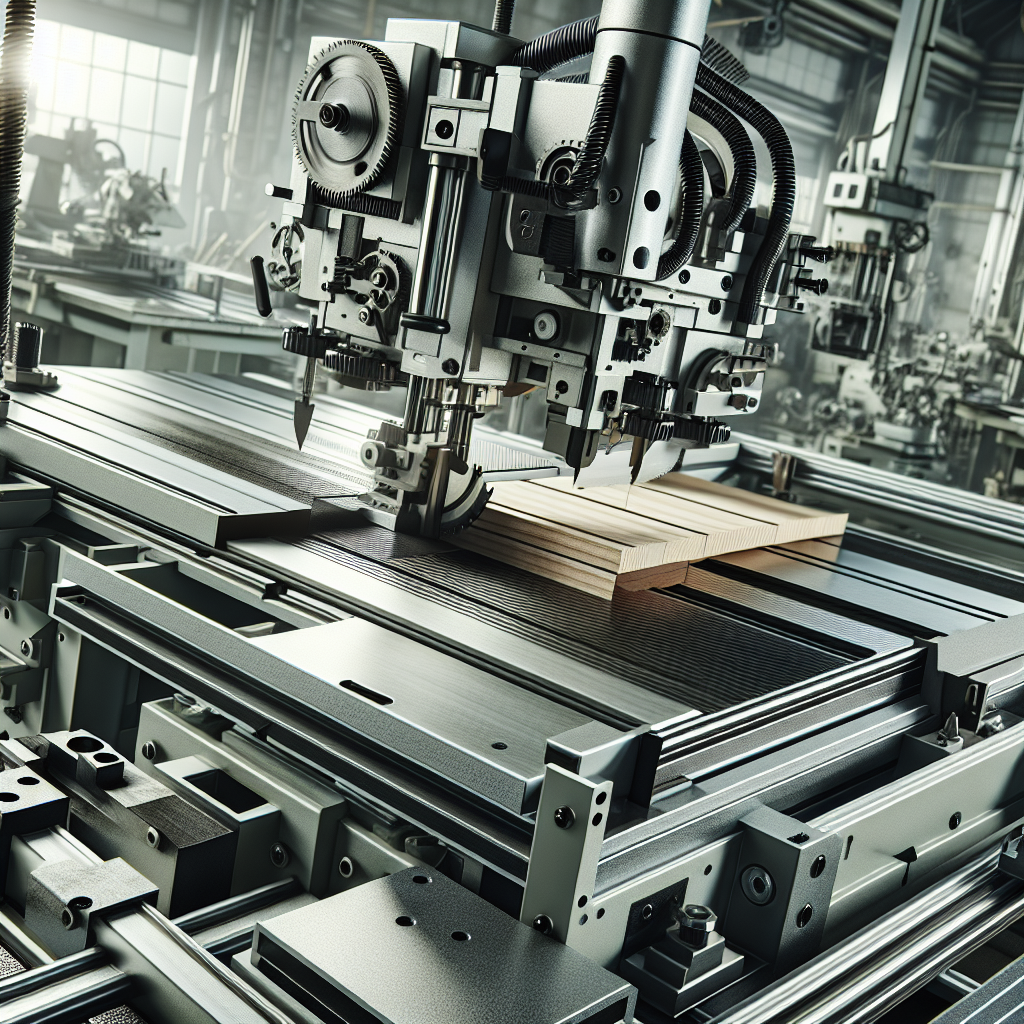

Woodworking machinery exporters play a crucial role in the global market, providing essential equipment to woodworking factories around the world. These machines are essential for shaping, cutting, and finishing wood products, making them vital for the production of furniture, cabinetry, flooring, and other wooden items. With advancements in technology, woodworking machinery has become more efficient, precise, and versatile, offering numerous benefits to manufacturers and traders in Egypt, Pakistan, Vietnam, Kenya, Saudi Arabia, UAE, Russia, and other global markets.

Technical Specifications

Woodworking machinery comes in various types and models, each designed for specific tasks in the woodworking process. Some common types of woodworking machinery include:

1. Table saws: Used for cutting wood into various shapes and sizes, table saws are essential for woodworking factories. They come in different sizes and configurations, with features such as adjustable fences, miter gauges, and blade guards for safety.

2. Planers: Planers are used for smoothing and flattening wood surfaces, making them ideal for preparing wood for further processing. They come in different sizes and capacities, with features such as adjustable cutting depth and feed speed.

3. Jointers: Jointers are used for creating flat surfaces on wood edges, ensuring a tight fit when joining pieces together. They come in various sizes and configurations, with features such as adjustable tables and fence angles.

4. Sanders: Sanders are used for smoothing wood surfaces and removing imperfections, making them essential for finishing wood products. They come in different types, including belt sanders, disc sanders, and drum sanders, each designed for specific tasks.

5. CNC routers: CNC routers are computer-controlled machines that can perform a wide range of woodworking tasks, such as cutting, carving, and engraving. They offer high precision and efficiency, making them ideal for complex woodworking projects.

Use Cases in Woodworking Factories

Woodworking machinery is essential for improving productivity, precision, and quality in woodworking factories. These machines enable manufacturers to automate various tasks, reduce labor costs, and produce high-quality wood products efficiently. Some common use cases of woodworking machinery in factories include:

1. Cutting and shaping wood: Table saws, planers, and jointers are used for cutting and shaping wood into various sizes and shapes, allowing manufacturers to create custom wood products according to customer requirements.

2. Finishing wood surfaces: Sanders are used for smoothing wood surfaces and removing imperfections, ensuring a high-quality finish on wood products. They can be used for sanding both flat and curved surfaces, making them versatile machines in woodworking factories.

3. Carving and engraving: CNC routers are used for carving intricate designs and patterns on wood surfaces, adding decorative elements to furniture, cabinetry, and other wooden items. They offer high precision and repeatability, making them ideal for complex woodworking projects.

Advantages Over Other Machines

Woodworking machinery offers several advantages over traditional hand tools and manual machines, making them essential for modern woodworking factories. Some key advantages of woodworking machinery include:

1. Efficiency: Woodworking machinery can perform tasks quickly and accurately, reducing production time and increasing efficiency in woodworking factories. They can handle large volumes of wood products with consistent quality, ensuring high productivity in manufacturing processes.

2. Precision: Woodworking machinery offers high precision and accuracy in cutting, shaping, and finishing wood products, ensuring tight tolerances and smooth surfaces. They can produce complex designs and patterns with ease, making them ideal for custom woodworking projects.

3. Safety: Woodworking machinery comes with safety features such as blade guards, emergency stops, and automatic shut-off mechanisms, reducing the risk of accidents and injuries in factories. They are designed to comply with safety standards and regulations, ensuring a safe working environment for operators.

4. Versatility: Woodworking machinery can perform a wide range of tasks, from cutting and shaping wood to carving and engraving intricate designs. They offer flexibility in manufacturing processes, allowing manufacturers to produce a variety of wood products with different sizes, shapes, and finishes.

Ideal for Importers and Traders

Woodworking machinery exporters offer a wide range of machines and equipment to importers and traders in Egypt, Pakistan, Vietnam, Kenya, Saudi Arabia, UAE, Russia, and other global markets. These machines are essential for setting up woodworking factories, expanding production capacity, and improving product quality in the woodworking industry. Importers and traders can benefit from woodworking machinery exporters in several ways:

1. Quality products: Woodworking machinery exporters offer high-quality machines and equipment from reputable manufacturers, ensuring reliability, durability, and performance in woodworking factories. Importers and traders can source top-notch machinery that meets their specific requirements and production needs.

2. Technical support: Woodworking machinery exporters provide technical support, training, and maintenance services to help importers and traders set up and operate woodworking machinery effectively. They offer guidance on machine selection, installation, and operation, ensuring smooth production processes in factories.

3. Customization: Woodworking machinery exporters can customize machines and equipment to meet the unique requirements of importers and traders, such as specific sizes, configurations, and features. They can tailor woodworking machinery to suit different woodworking projects and applications, ensuring optimal performance and efficiency.

4. Competitive pricing: Woodworking machinery exporters offer competitive pricing on machines and equipment, allowing importers and traders to source cost-effective solutions for their woodworking operations. They provide value-added services such as discounts, promotions, and financing options, making woodworking machinery affordable and accessible to a wide range of customers.

Connecting Buyers with Reliable Suppliers

Woodenb2b.com is a leading online platform that connects buyers with reliable woodworking machinery exporters and suppliers worldwide. This platform offers a comprehensive database of woodworking machinery, tools, and accessories from trusted manufacturers and distributors, making it easy for importers and traders to find the right products for their woodworking needs. Woodenb2b.com provides a user-friendly interface, advanced search options, and detailed product information, enabling buyers to compare prices, features, and specifications of woodworking machinery before making a purchase.

Woodenb2b.com also offers value-added services such as buyer protection, secure payment options, and logistics support to ensure a smooth and seamless buying experience for customers. Importers and traders can browse a wide selection of woodworking machinery, request quotes, and negotiate deals with suppliers directly on the platform, saving time and effort in sourcing woodworking equipment. With Woodenb2b.com, buyers can access a network of reliable suppliers, source high-quality woodworking machinery, and grow their woodworking business in the global market.

In conclusion, woodworking machinery exporters play a vital role in the global market, providing essential equipment to woodworking factories around the world. These machines offer high efficiency, precision, and versatility in cutting, shaping, and finishing wood products, making them ideal for importers and traders in Egypt, Pakistan, Vietnam, Kenya, Saudi Arabia, UAE, Russia, and other global markets. With advancements in technology and a wide range of products available, woodworking machinery exporters offer quality machines, technical support, customization, and competitive pricing to meet the diverse needs of customers. Platforms like Woodenb2b.com help connect buyers with reliable suppliers, making it easier to source woodworking machinery and equipment for woodworking operations worldwide.

Why Importers and Factories Should Choose a Sliding Table Saw Machine

Sliding table saws are essential tools in modern woodworking industries due to their precision, speed, and versatility. Whether you’re importing into Egypt, Kenya, or Vietnam, this machine can significantly improve productivity.

Technical Specifications

- Power: 4 kW – 7.5 kW

- Blade Diameter: 300mm – 400mm

- Adjustable Cutting Depth and Angle

- Industrial-grade Aluminum Table

Where to Buy Quality Sliding Table Saws?

If you’re looking to source directly from China or need trusted suppliers in the Middle East, Africa, or Asia, woodenb2b.com connects importers and factories with verified machinery suppliers.

📌 Looking for more information? Visit us at woodenb2b.com — Your B2B Source for Woodworking Machinery.

RELATED POSTS

View all